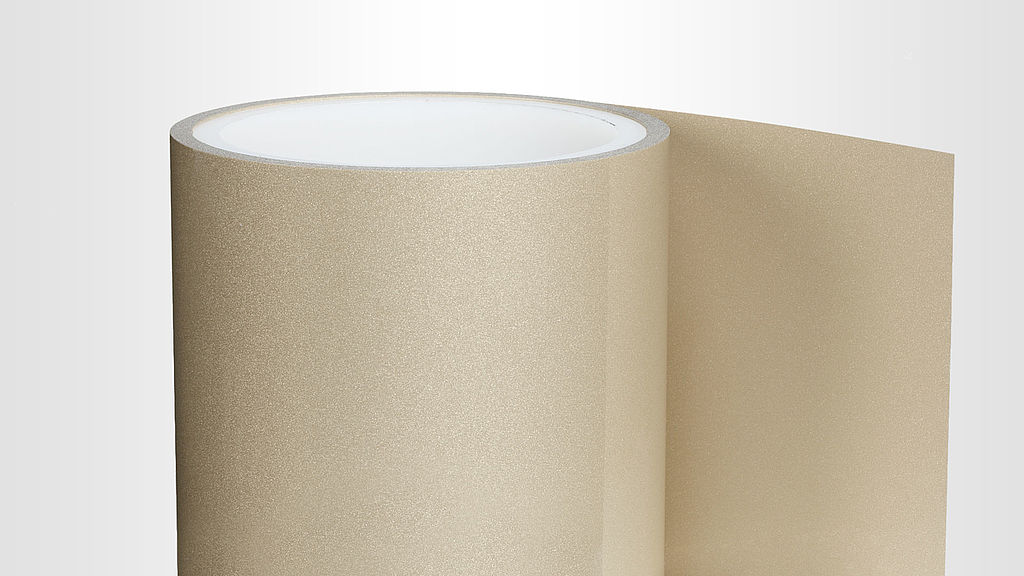

Materials used

Metal particle interspersed polymers: These offer excellent conductivity and are flexible in their application.

Metal foils: Commonly used materials are copper or aluminium, which are known for their conductive properties and often serve as a carrier material.

Conductive adhesive: Often based on silver, this allows current to flow through the tape itself and provides a strong, conductive connection.

To summarise, electrically conductive adhesive tapes are a key component in modern automotive engineering. They contribute to the realisation of safe, reliable and powerful vehicles while supporting grounding and EMC safety, which underlines their importance in an increasingly electrified vehicle landscape.