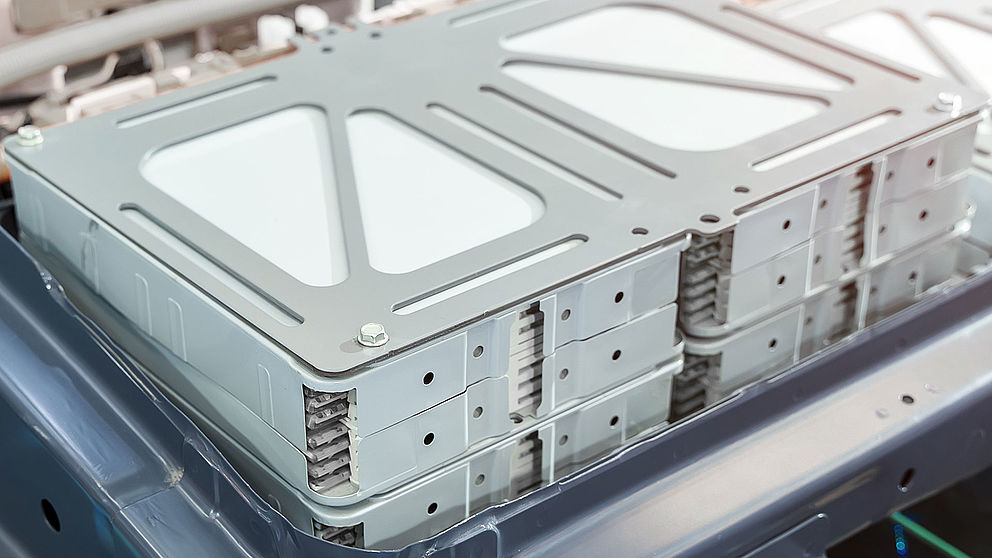

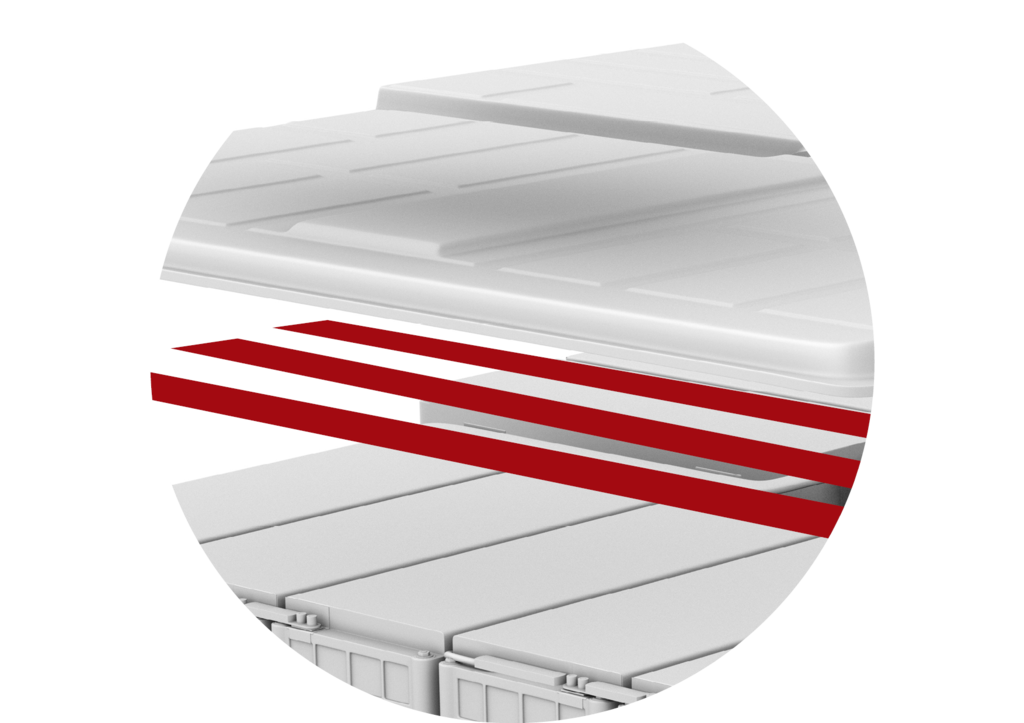

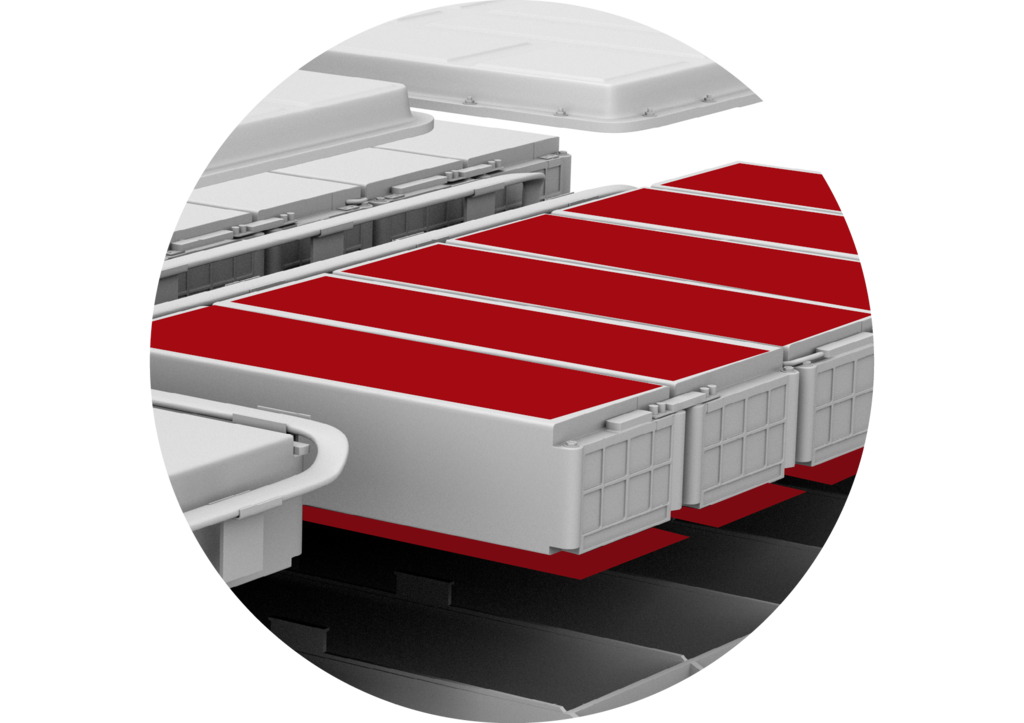

In case of damage or short circuits, a battery can overheat and, in the worst case, cause fires or explosions. Special adhesive tapes can slow down or prevent the spread of fire by acting as a barrier and delaying flame propagation between components. This significantly enhances safety:

1. Prevention of Thermal Runaway: Special adhesive tapes prevent heat from spreading to adjacent cells, reducing the likelihood of fires.

2. Improvement of Structural Integrity: The additional barrier improves the battery's structural integrity in the event of an accident.