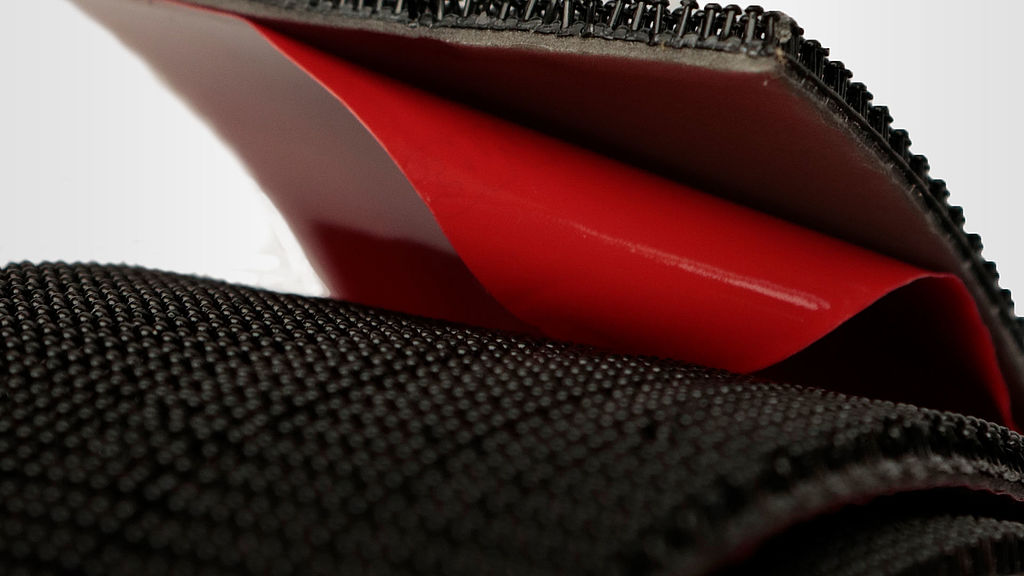

3M Dual Lock is a self-adhesive, re-releasable fastening system. It consists of small black or transparent polyolefin hemispherical heads on a short stem that form a firm but releasable bond when they are pressed together. Depending on the design, these heads are arranged in a straight or undulating pattern.

On the other side is either a synthetic rubber or acrylic adhesive. The synthetic rubber adhesive has high immediate adhesion as well as good bonding strength on low-energy surfaces such as PP, PE and powder-coated materials. The acrylic adhesive, on the other hand, has high shear strength even at higher temperatures and on rough surfaces. It has excellent final tack as well as high resistance to ageing, UV, chemicals and plasticisers.

![[Translate to Englisch:] Dual Lock [Translate to Englisch:] Dual Lock](/fileadmin/_processed_/a/b/csm_Dual-Lock-nah2_ff3c604324.jpg)