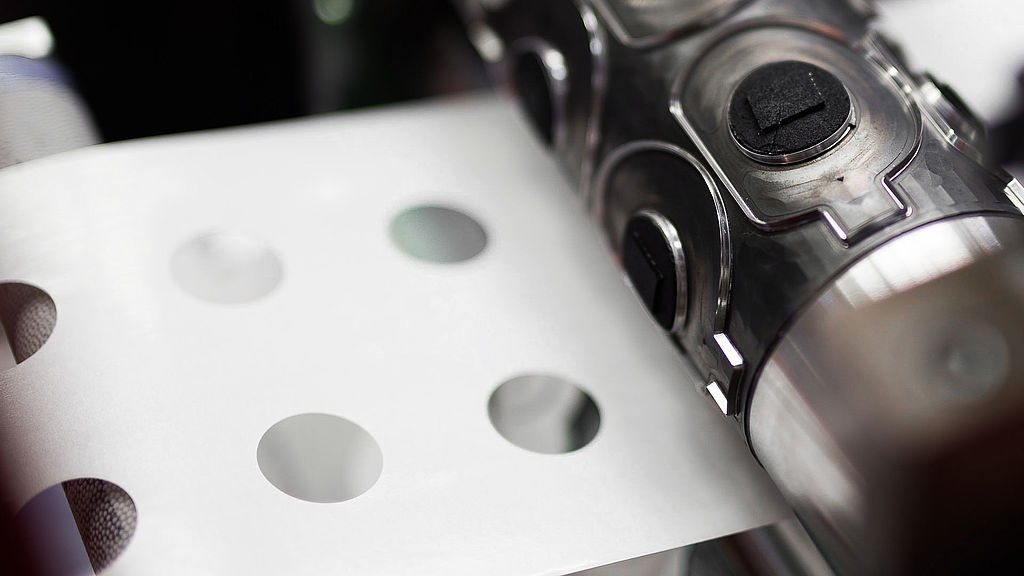

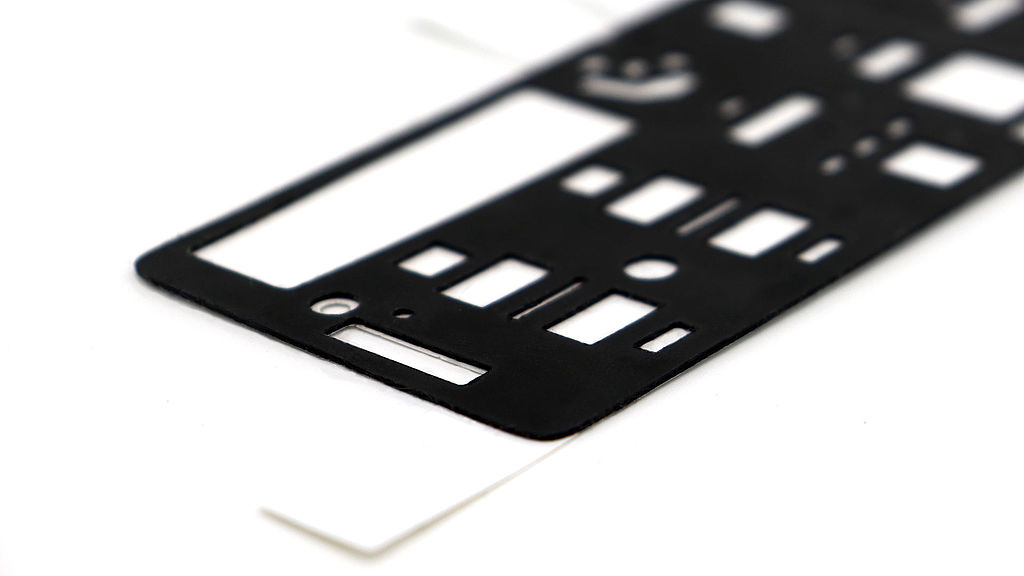

A critical point that directly affects cost efficiency in production is material utilization. Customized tape parts can make a significant difference here. In many production environments, standard tape is used in roll form, which is often cut on-site to meet specific needs. This process frequently leads to excess material and waste.

Waste Reduction Through Precisely Manufactured Parts

By using custom-made tape parts, each piece is produced exactly to the required dimensions and shapes. This minimizes waste since no additional cutting is necessary. The precise fit means that the tape is applied without overlaps or missing areas, which also contributes to material savings.

Measurable Benefits of Switching to Custom Solutions

Companies that switch to custom-made tapes often report a reduction in material wastage by 10% to 25%, depending on the complexity of the applications and the accuracy of previous methods. In some cases, especially when high-quality or specialized materials are used, the savings can be even higher. These savings not only contribute to cost reduction but also improve the sustainability of production by reducing waste.